NOGS–ESP Hopper Continuous Level Measurement

NOGS–ESP Hopper Continuous Level Measurement

Get precise and continuous ESP coal fly ash hopper level measurements with 10x more efficiency

Our NOGS (Naturally Occurring Gamma Ray Sensor) is the most advanced continuous level measurement device for ESP Fly Ash Hoppers. Installed outside the Hopper Plate without needing any cutouts or shutdowns for the ESP Hopper, this instrument is a dream for operators because of its reliable measurements and easy maintenance.

Request a QuoteHow It Works

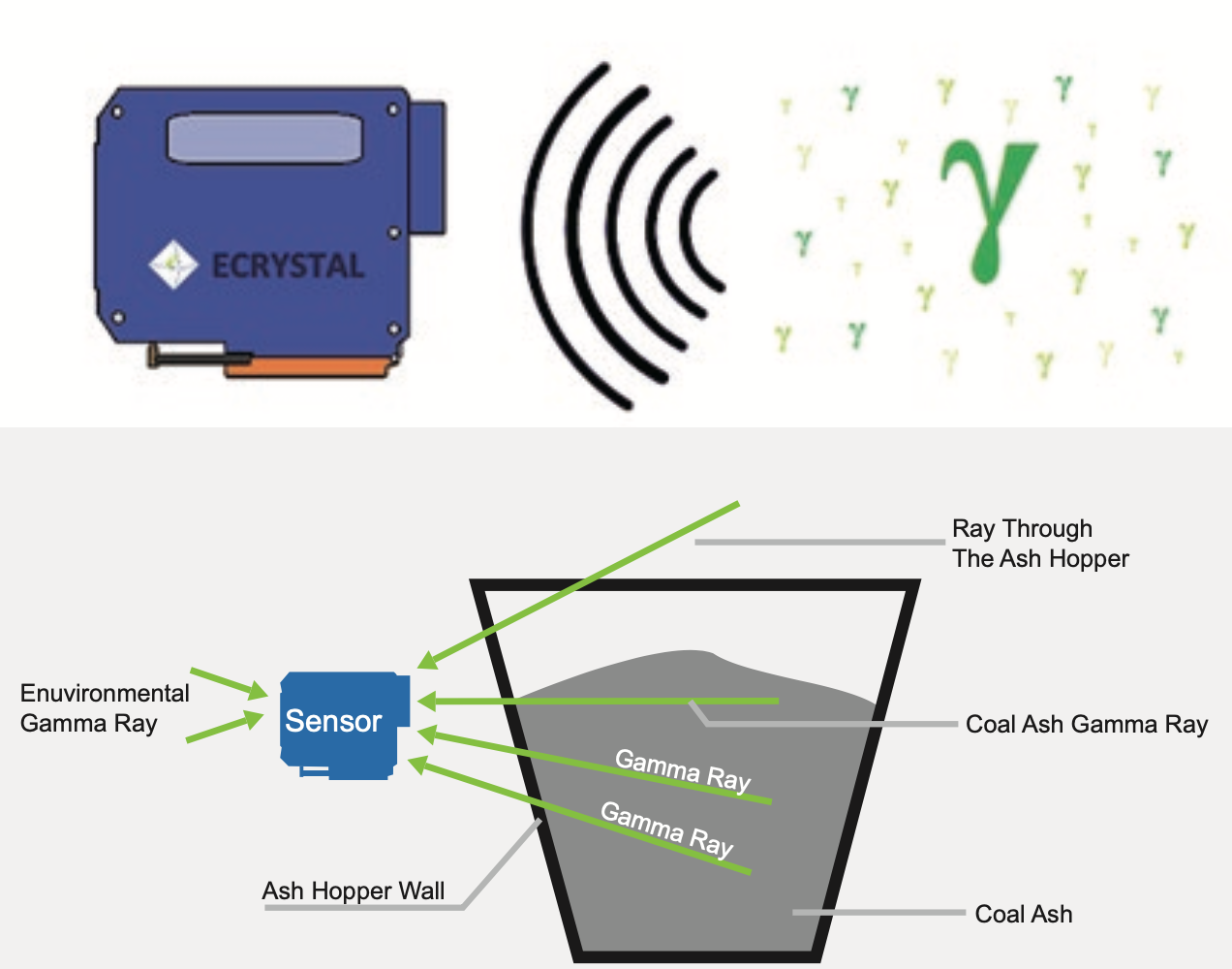

Based on the NOGS γ-ray detection technology, this device accurately detects trace amounts of natural radionuclides in fly ash by effectively identifying low-level gamma ray changes using random signal recognition technology.

Equipped with a specialized built-in processor, it gives accurate measurements by distinguishing between gamma rays emitted by fly ash and background noise. Unlike traditional ESP hoppers that rely on radioactive sources, the NOGS sensor (a scintillator) is unique as it functions solely as a detector, using fly ash itself as the gamma ray source. It’s especially useful for managing the first two ESP hopper fields, which handle the most ash.

Specifications

Preferred Applications: ESP Coal Fly Ash Hoppers

Measuring Range: 10m

Operating Temperatures: Independent as outside the Hopper

Operating Pressure: Independent as outside the Hopper

Signal Output: 4-20mA and 2 SPDT Relay Contacts (4 Wire System)

Supply Voltage: 100–240VAC

Power Consumption: Max 10 VA

Safety: Explosion Proof Certification

Download our catalog for all the information you need!

Download Now

Industries Served

Industries Served