Level Measurement Transmitters: Working & Types

A level measurement transmitter is an apparatus that is suitable for determining the level of a certain liquid or a bulk-solid at a particular time. They are inherently different in their functioning from level switches as level switches indicate when the level of a material reaches a certain level while level transmitters provide continuous level measurement.

They are used in multiple industries ranging from material handling to food and beverage, power, chemical, and water treatment industries. There are mainly two classifications of level measurement transmitters: direct and indirect level transmitters. The former is ideal for small level changes, while the latter is used for measurements that are either too high or too low level.

If we categorize level transmitters according to their working principles, there are various types of them available in the market, all fit for a different purpose. For instance, hydrostatic level transmitters operate through the pressure exerted by the fluid, capacitance level transmitters operate through a capacitor, and ultrasonic level transmitters operate through ultrasonic waves.

But what is common is that all types of level measurement transmitters use either the fluid’s weight, or its pressure head, or its position in the container to provide the measurements.

In total, there are 7 different types of level measurement transmitters, all of which work differently and are suitable for different purposes:

- Capacitance Level Transmitter: It uses capacitors to store energy between the two insulated electrodes. If there is more liquid, the energy capacity of the capacitor increases, and if there is less liquid, the energy capacity decreases. It is the variations in the capacitance value that helps to calculate the fill level of the tank.

- Magnetic Fill Transmitter: It uses a magnetic object suspended in a buoyant float usually placed inside a narrow auxiliary column to restrict any lateral movements. A different magnetic device is used to measure the movement of the float as the float sits on the top of the liquid. The float’s tendency to rise or sink in harmony with the level of the liquid adds to its accuracy.

- Hydrostatic Level Transmitter: It is also known as pressure level transmitter as they determine the fluid contents by measuring the pressure of the resting body of fluid within it. In order to ensure accurate measurement, it requires the liquid’s density to remain consistent.

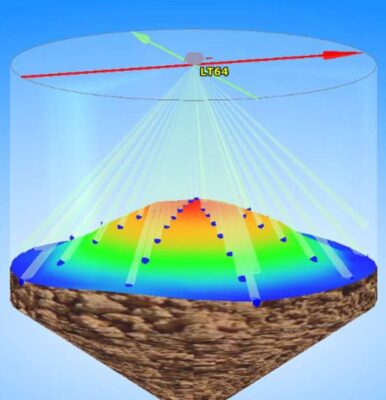

- Radar Fill Level Transmitter: It uses radio wave emissions to measure the fill levels. It is usually mounted on the top of the tank filled with the liquid. A radar signal is then emitted into the liquid and a reflection of that signal is received. It then accurately calculates the fill level of the tank by analyzing the time it took for the signal to reflect.

- Ultrasonic Level Transmitters: It is similar to radar fill level transmitter in its functioning. It uses an ultrasonic transducer that is mounted to or near the top of the tank filled with the liquid. It sends out an ultrasonic pulse which is then reflected. A sensor is used to calculate the fill level based on the time taken to transmit and receive the signal.

- Liquid Level Transmitters: It is primarily used for detecting interfaces between two different liquids by measuring the head pressure of the liquid. It is highly suitable for liquid-level sensing in transport tanks and storage tanks.

- Guided Microwave Level Transmitters: It uses a microwave pulse that is transmitted through the sensor rod/cable. On hitting the surface of the liquid, it travels back up the sensor rod and back to the transmitter housing, where electronics are integrated to determine the filling level.

EIP is one of the world’s leading manufacturers of Level Measurement Transmitters. It offers 3D Radar Level Transmitter, 140 GHz Radar Level Transmitter, NOGS – ESP Hopper Continuous Level Measurement, Ultrasonic Level Transmitter, Guided Wave-Radar Level Transmitter, Electromechanical Silo Pilot Level Transmitter, and more.