3D Level Scanner for Silos

Silos and bunkers store a massive amount of inventory. There is a variant of Silo level measurement technology such as Radio Frequency, Ultrasonic, Laser, Radar and Nucleonic. Each of these technologies has its shortcomings which restrict it from use in Silos and bunkers. The common among all is the problem of single point beam generated which fails to work on an uneven level profile.

Silos and bunkers are used to store bulk materials. Traditionally, the Silos store dry Bulk Solids and Powders. The structure of a Silo is a tall structure and the lateral dimension is relatively smaller. This poses design challenges like rat-holing, arching, and bridging. As a result, the flow of powder and solid level measurement accuracy poses quite a challenge. The inventory stored in Silos and Bunkers is accompanied by a lot of dust which prohibits a lot of traditional levels measurement technology to deliver output accurately and efficiently. Apart from dust, the other challenges in measuring powder products are the uneven surface and maintenance cost. 3D Level Scanner is a One Stop Solution for the above challenges giving the most innovative Level Transmitter for the market till date.

Challenges

3D Level Scanner

Principle

Advantages

Challenges

The majority of powder or solid level measurement devices measure only the top or bottom of the predefined level. They are usually used to send out alerts when a min or max level is reached. These devices are accurate and affordable, however, they measure only the level at a point that doesn’t give an accurate image for powders or solid material.

Realistically, powders and solids deposit in an uneven fashion on the surface, the peaks are distributed at the surface hence, one-point level measurement is inefficient.

Another challenge posed by powders and solids is the nature of the inventory. Often they damage the sensors and an accurate Silo level measurement is not achieved. Additionally, these materials are bulky and difficult to handle which makes remote management a requirement. Solid level measurement becomes even more tricky as the solids do not flow consistently and evenly. Hence, multi-point measurement of the level is required to gimmick the most accurate level inside silos and bunkers.

3D Level Scanner

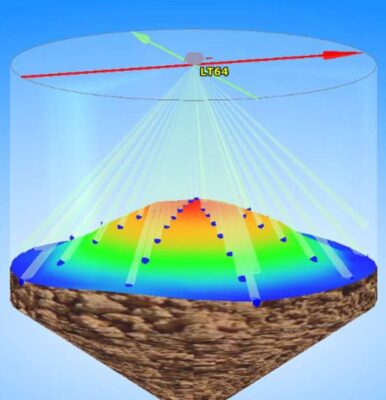

3D level scanners provide holistic imaging of the level of the inventory inside the silos. Solid level measurement has been revolutionized with the introduction of 3D level scanners that detect the level of material at multi-points. The 3D level scanner is based on a non-contact continuous level transmitter technique which is appropriate for not just measuring irregular surfaces but also provides imaging inside the silos. The technology is based on the acoustic pulse system which helps in mapping a representation of the interiors of closed and/or open silos, bins, and bunkers. It also helps in detecting sidewall buildup.

Principle

The 3D level scanner consists of 3 antennas. These antennas work as trans-receivers that transmit low-frequency pulses and receive them back to create an image of that point. The 3D level transmitter receives echoes of the pulses and measures the distance based on the time of flight principle and the beam angle. The beam angle is important as it helps in projections of visual representation of the material pile.

To detect Silo level measurement, the digital signal processor unit analyses each echo to efficiently measure all levels such as maximum, minimum, average along with the volume and mass of the goods stored in the silos. To measure the volume and mass, the 3D level transmitter assigns each echo received with a weight instead of averaging it out. This weight is later being used to digitally map the points of level and measure the mass and volume accurately irrespective of the type and size of the material that is being stored.

The biggest advantage of using a 3D level scanner over other technologies is the wide-angle scanning that it offers. The range of the beam angle that a 3D level transmitter has is between 30 to 70 degrees. With such a wide-angle it can point and scan all the peaks and dips on the surface.

The data contained from scanning the surface measures cone up and down conditions along with buildup against the sidewall. The data achieved from the 3D level transmitter is run through advanced algorithms. The algorithms measure data points against the parameters of the silo structure and estimate the present volume in the Silos. This helps in monitoring the continuous level of material in the silos.

Since the acoustic sensor is a completely non-contact device, it is far from coming in contact with the material which increases the life of the device. Also, the results are highly accurate and reliable even with heavy and sticky materials. The maintenance cost is also considerably reduced as there are replacement of parts like probes or wires, or cables that may have wear and tear.

Self Cleaning Feature

One of the key features of a 3D level scanner is that it has a self-cleaning ability which does not require any additional air for cleaning. The design and material of the scanner are chosen in such a way that it prevents the build-up of free dust that is usually found at the top of the silos. The 3d level transmitter emits pulses that make a special sound like ‘chirping’ that resonates and creates vibrations that support the scanner to self-clean and dust off any build off from the suspended particles. The self-cleaning features reduce overhead costs of maintenance and manpower time.

The scanners are accompanied by supporting algorithms or software that make it viable to access the measurements remotely. The monitoring can be done for all levels and for detecting the volume and mass of the material stored in the silos.

To achieve a highly accurate reading from a 3D scanner external variables like size and structure of silos should be measured and stored in the algorithm. Also, the device should be installed in such a way that it has objection-free access to the inventory surface.

Advantages

3D level Scanner offers several advantages to its counterparts.

Multi-point scanning for irregular surface

Continuous measurement of level

Non-contact based

Works with all types of powders, solid materials

Additional detection of cone up, cone down, and sidewall build-up

Mapping and visual representation of material inside the silo

Detection of maximum, minimum, and average level of inventory

Wide range of beam angle up to 70 degrees

Unaffected even in high amounts of dust

Works efficiently in high-temperature variations

Recommended for hazardous materials

Low maintenance cost

Complete remote monitoring

Works on both analog and digital communications

Self-cleaning ability