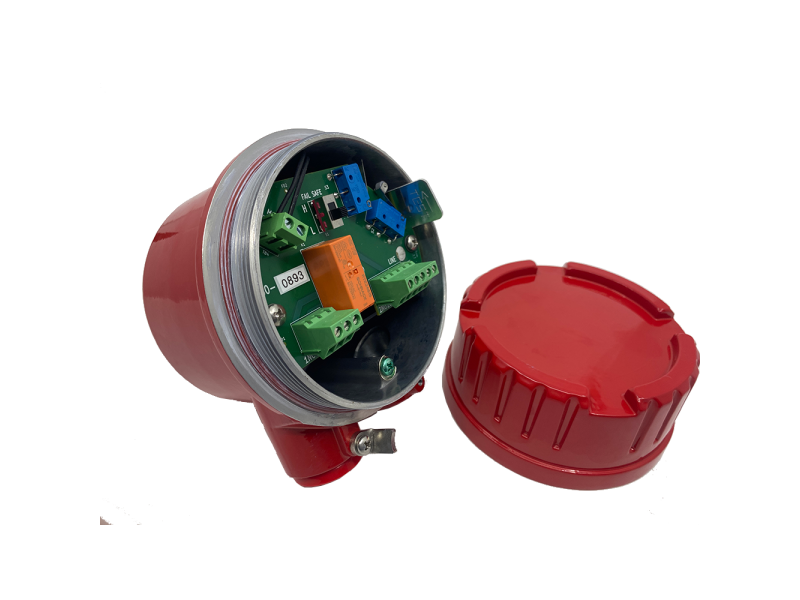

Rotary Paddle Level Switch

Rotary Paddle Level Switch

Get the most efficient tool for hassle-free level monitoring!

Rotary Paddle Level Switches are a common point-level indicator used for high, mid, and low-level material detection in bins, tanks, and silos. They are wired to a horn, alarm, or light panel to send an alert when the material reaches the desired level. Our switches come in standard and fail-safe versions, with options for top or side mounting, thick bin walls, or corrosive materials. The BMRX model is especially durable, with explosion proof housing, a de-energized motor operation, a slip-clutch protection, and a four-bearing drive shaft.

Request a QuoteHow It Works

The rotary paddle level indicator detects the level of dry bulk solids in bins, tanks, and hoppers. Mounted on the top or side, it alerts operators when bins are full via a light or horn. Its motor shuts off when material is detected, saving energy costs and extending motor life.

For high-level control, the paddle rotates until material blocks it, triggering an alarm or stopping filling to prevent overflows. For low-level control, it starts rotating again, sending an alert or restarting equipment.

CE approved and explosion-proof, it’s suitable for hazardous environments with Class I, Groups C and D, Class II E, F, and G listings.

Specifications

Preferred Applications: Solids

Operating Temperatures: –40°C to +150°C

Operating Pressure: –0.2 to 10 bar

Signal Output: 1 DPDT

Supply Voltage: 24 VDC/ 110 VAC/ 230 VAC

Power Consumption: Max 3 W @ 24 VDC

Material Density: 2 lb./cu. ft. to over 100 lb./cu. ft.

Safety: Explosion Proof

Download our catalog for all the information you need!

Download Now

Industries Served

Industries Served