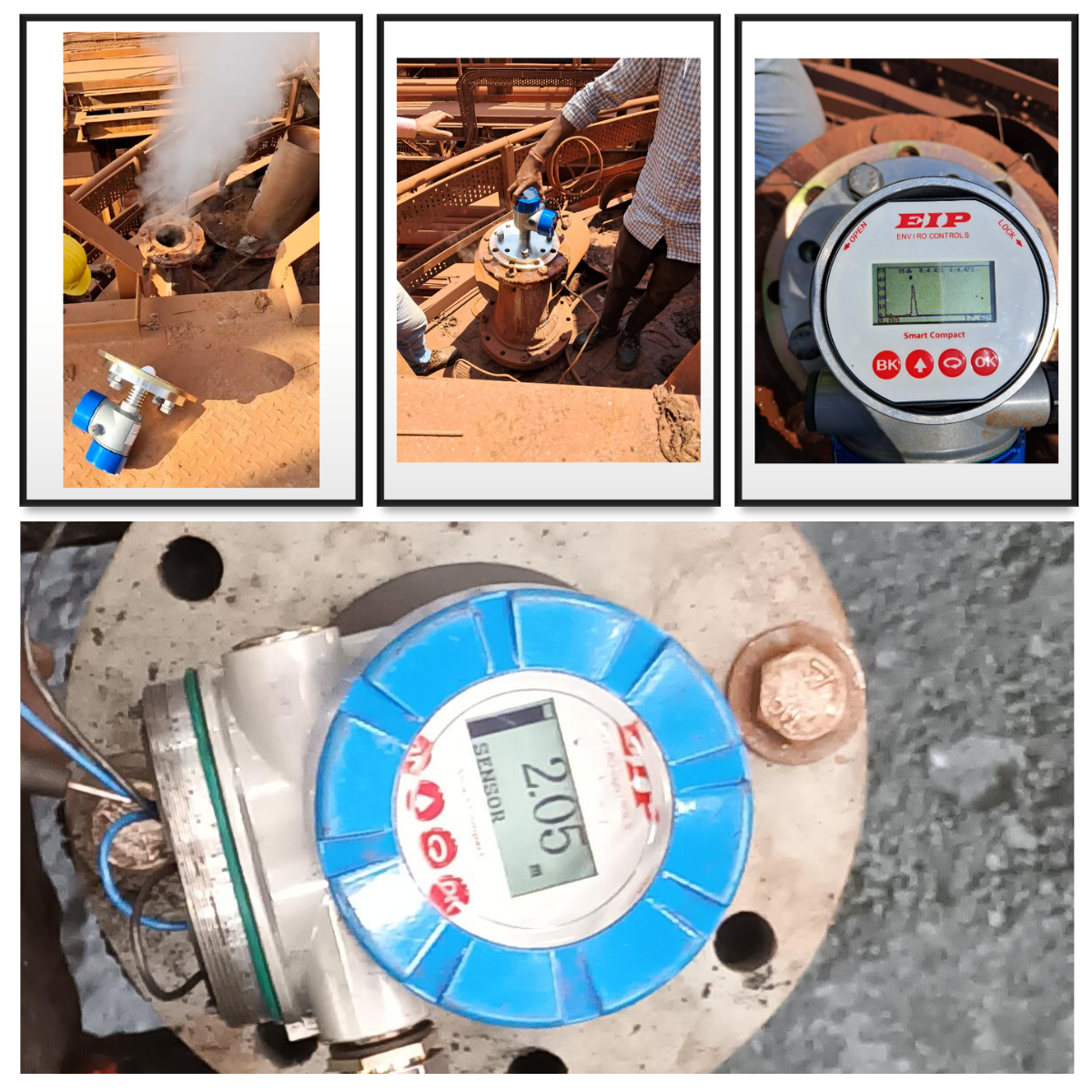

Non Contact Radar Level Transmitter

Non Contact Radar Level Transmitter

Accurate and reliable level measurement with advanced noise cancellation algorithms

The Non Contact Radar Level Transmitter family includes radars with frequency ranges of 6.3 GHz and 26 GHz pulse radar, as well as 80 GHz FMCW Radar. These radars come in various configurations and process connections to meet specific customer requirements. Known for their proven performance and high level of customization, these Radar Level Transmitters are widely used and are in high demand among our customers.

Request a QuoteHow It Works

The Radar Level Transmitters are excellent devices for non contact level measurement. The microwave impulses, emitted by the radar’s antenna, travel at speed of light and a part of their energy, reflected by the surface of the medium to be measured, is received by the same antenna. The period of time (flying time) between the emission and the arrival of the impulses, is proportional to the existing distance between the antenna and the surface of the medium to be measured.

The electromagnetic wave travels at a very high speed (nanosecond), so it is difficult to identify it: Our Radar Level Transmitters however, through it’s integrated management system, use a suitable demodulation technology that allows them to identify the period of time between the emission of the impulses and their corrected reception and, consequently, determine and measure the level.

The EIP_WARE software allows configuration via PC using HART communication. An integrated temperature sensor ensures accurate real-time measurements. These transmitters are safe for both humans and the environment and can be used in metallic or non-metallic tanks.

Specifications

Preferred Applications: Solids, Liquids and Slurries

Measuring Range: 70 meters/ 120 meters

Operating Temperatures: –40°C to 400°C

Operating Pressure: –0.2 to 40 bar

Signal Output: 2 Wire/ 4-wire with 4 – 20 mA/HART

Emitting Frequency: 6.3 or 26 GHz or 80 GHz

Supply Voltage: 20 to 32 VDC/ 110 VAC/ 230 VAC

Power Consumption: Max 1.5 W @ 24 VDC

Safety: Explosion Proof and Intrinsically Safe

Download our catalog for all the information you need!

Download Now

Industries Served

Industries Served