Recommended Products

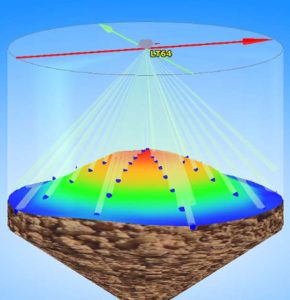

3D Radar Level Transmitter

A revolutionary technology that measures at multiple points inside the Silo to create a real-time 3D profile and provide accurate

Show ProductUltrasonic Level Transmitter

Non-Contact Ultrasonic Level Transmitter is a versatile family of devices that operates with a frequency range measured in kilohertz (KHz)

Show Product

Solution:

Solution: