3D Acoustic Level Scanner

3D Acoustic Level Scanner

Effortlessly measure the level and volume of bulk solids and powders in silos with accuracy and ease!

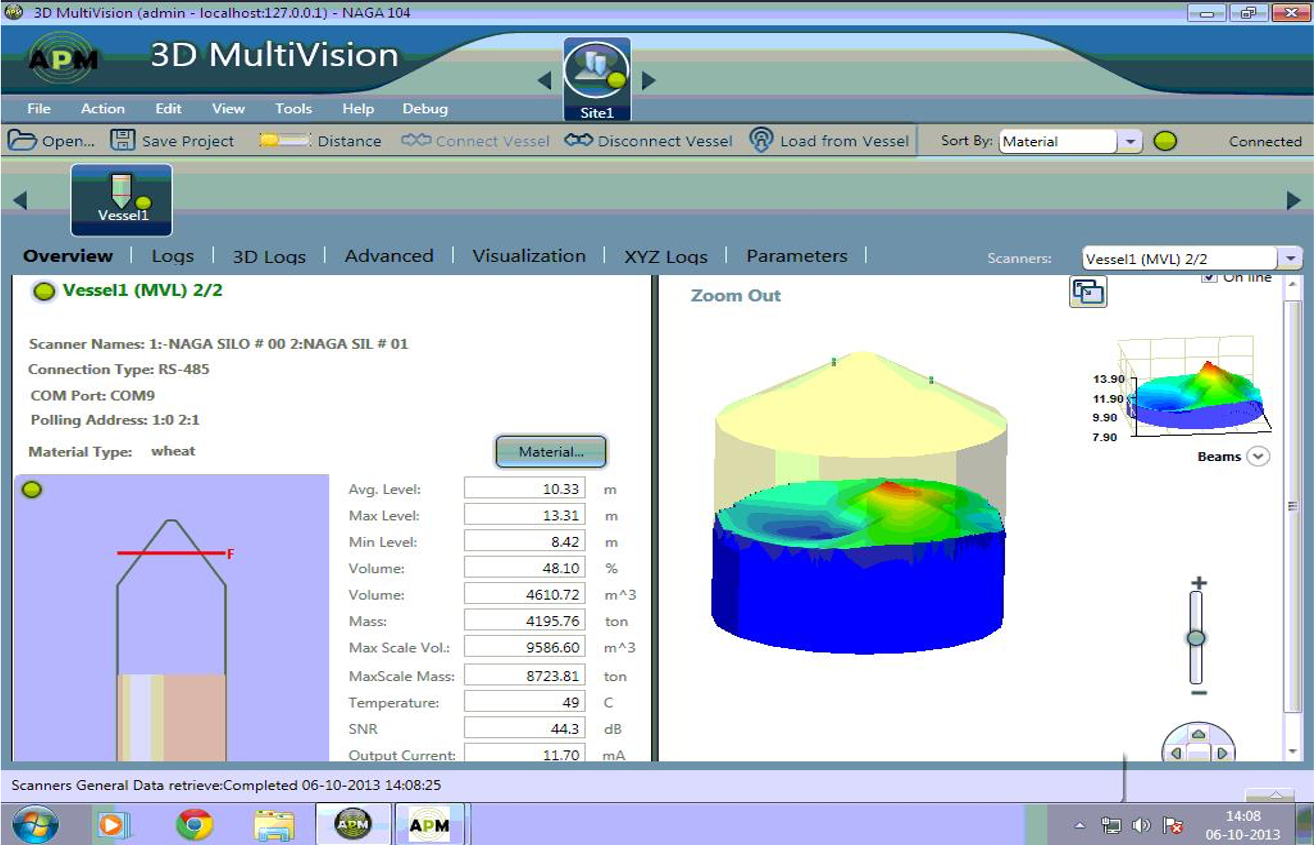

3D Level Scanner is an Acoustic continuous Level Transmitter that measures multiple points on a material’s surface, providing continuous, non-contact inventory volume measurement that accounts of irregular material topography. This advanced acoustic-based technology is proven to perform in powders and bulk solids contained in bins, silos, domes, warehouses, as well as open bunkers and piles. Unique 3D mapping capabilities provide a visual representation of bin contents, detecting cone up or down as well as sidewall buildup

The 3D Level Scanner solves the 3 major challenges of Level Measurement for Solids and Powders (where conventional methods are not able to solve the problem)

- Uneven profile due to angle of repose

- Heavy Dust

- Maintenance

How It Works

3D Level Scanner employs an array of 3 antennas to transmit low frequency pulses and to receive echoes of pulses from the contents of the silo, bin or other container. Using 3 antennas the unit measures not only the time / distance of each echo but also its direction with beam angle of 30-70 degree. The device’s digital signal processor samples and analysis they receive signals to provide very accurate measurements of the maximum level, minimum level, average level volume and mass of the stored contents and also generates a realtime 3D representation/ profile of the contents within the container Hoppers for display on remote computer screen.

The 3D LEVEL SCANNER working on the Low Frequency Acoustics have three major advantages

- Beam Angle of 70 Degree to cover the entire Silo Surface Area

- Works well with the Dusty environment (Based on Law of Diffraction)

- Self-Cleaning ability and does not require any air for cleaning.

Specifications

Preferred Applications: Powders and Solids

Measuring Range: 70 meters

Operating Temperatures: -40°C to +185°C

Operating Pressure: -0.2 to 3 bar

Signal Output Options 4-wire 4 – 20 mA/HART/RS-485/Modbus

Emitting Frequency: 2 KHz to 10 KHz

Supply Voltage: 20 to 32 VDC

Power Consumption: Max 1.5 W @ 24 VDC

Download our catalog for all the information you need!

Download Now

Industries Served

Industries Served